Mechanical Design & Machine Design

This week was a hard one. When i called Alban to plan what we can do for this groupe assignement, he explain to me he have put the formation on stand-by for this years.

Ok no worry i'm asking on the issues Neils created for this week lab collaboration & waiting some response.......

When waiting i start to plan my own machine design but finally Tuesday i find somebody to collaborate on a project.

Welcome Babasile Oladele

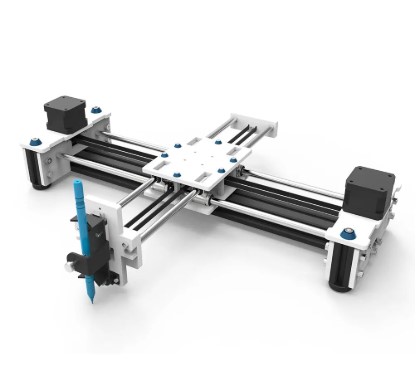

Starting to plan the project let's go, we are making a XY ploter.

Basile start to prepare the Group documentation when i do the CAD design. And after he is in charge of the fabrication in his Fablab.

----- Link to Basile Documentation -----

The inspiration of the project:

You could see it here

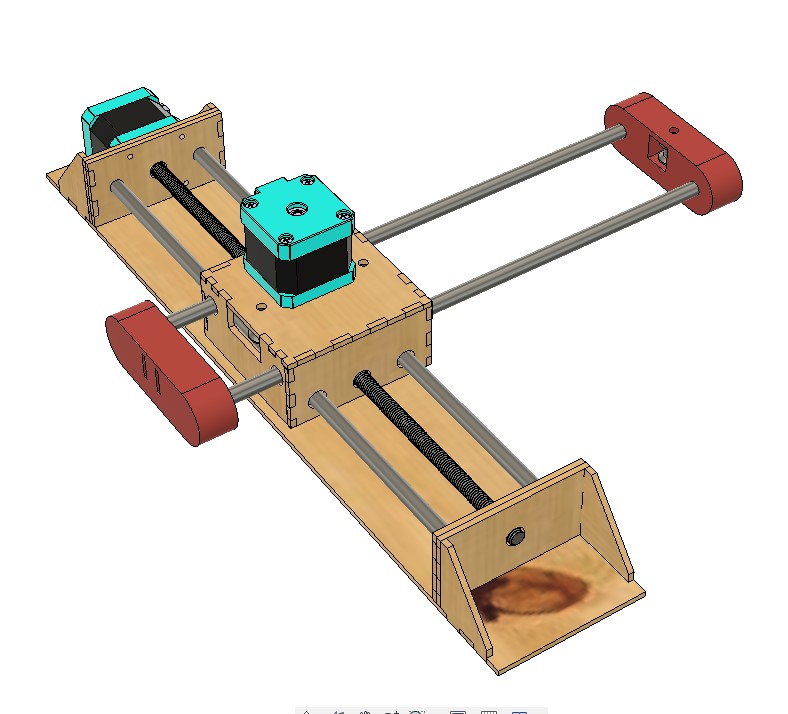

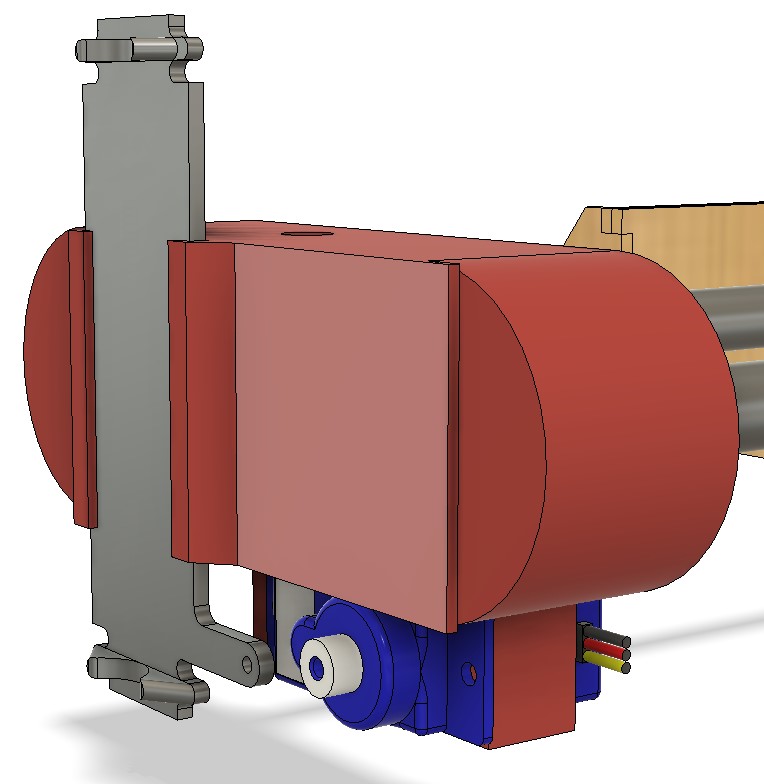

The CAD design:

Because i don't have acceess yet to a lab, the fabrication process is for Basile, for this reason i made my design with the list of material he have access.

- LM8UU linear bearing

- 8mm Smooth rod

- 3mm thick plywood

- Nema17 Stepper motor

- 8mm threaded rod

And the machine he have access to fabricate it:

- A Trotec Speedy100 laser cutter

- A Ultimaker 2 for 3D print

For the Design i taking inspiration from Jake's modules & from Nadya Peek modules

The plan is to redesign the modules to make a simple plywood Pressfit model using a Stepper motor for each X & Y axis.

One of this axis is moved by a threaded rod & the other one moved by a GT Belt system.

After a small night of rush designing i'm pretty glad of my design.

When Basile start the fabrication we facing some problem, when i converted the file into DXF an error occured and altered the dimension....

Normaly this box is 80 *80 mm large.

I send a correct converted file this times and basil could start to make the machine.

On the week at the ends of the days we spends one or two hours on what's app. Basile explained to me the different issues he have on the fabrication & me doing the corrections to fix it.

Finaly come the time, i'm feelling quite useless to basile ( online support every times and loking for solutions ^^). We attacking the software part of this project.

Spending a lot of time on phone to try to find different solutions to different issues he encounters but, for myself, without seeing the machines some hard time to understand.

But Finaly after some little conseption change and with some great ways to improve it. (get the servo working to up & down the pen / add some limitt switch to facilates the positionong)

Our plotter is working.

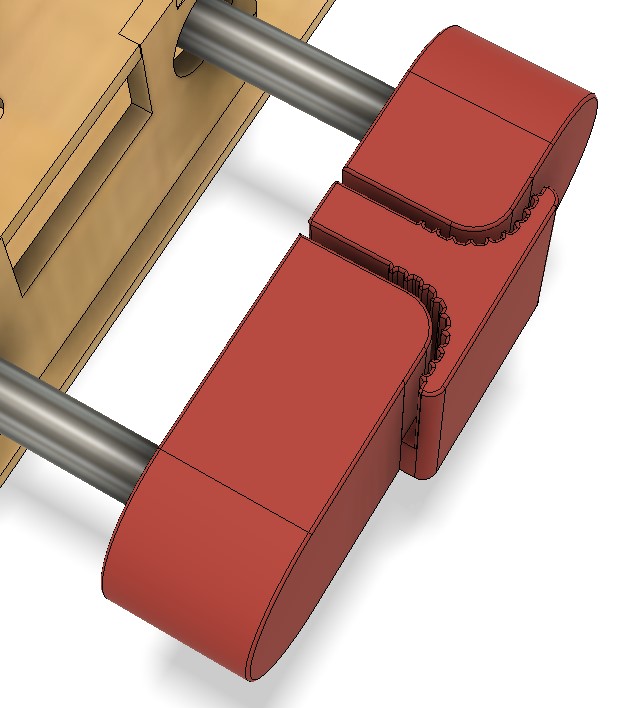

The two parts of the pen axis is design to be made with a 3D printer, one design for the pen holder & the other one with a blocking system for a easy GT Belt tensions.